Hi Vishnu Patil here we're going to look at the dry type transformer the hermetic type transformer and the conservator type transformer we're going to look at the transformer components such as the core and winding and then we're going to look at some of the other components that you're likely to see such as the bushings gas actuated relay temperature thermometer and the dehydrator breather.

So let's hang in there and we can start by looking at the heart of the transformer which is to convert the core so here we have a 3D model of the transformer core. We will spin a little bit because you can see that the core has three limbs and these three organs inform us. Is that this is a three phase transformer and the bottom of the transformer core is known as Yoke and in the middle these three to two Dow is known as organs of each factor is associated with one phase. The transformer core itself is usually clamped together using adhesive or some stripes. If we look at the bottom here you can see these three stripes are here and you will see that there are also two or three stripes on the other side so that the transformer core is clamped together. And it is clamped together because the core is not a solid block of metal is actually a series of metal sheets. Before we got these straight lines, these straight lines show us that the sheets are of different geometry and that you have clamped them together, you can get this wavy pattern if we can see I can do this. It can also go to another limb and look here and that is because the core is no longer cylindrical, because we have clamped these very thin laminate sheets together in the car. That we want to reduce the current losses and Eddie histresisa.

So we will clamp all the sheets of metal together. One of the organs is formed and then we will plant the metal sheet pieces together, each sheet is now insulated from its neighbor in order to form the nooks and the bottom of the transformer call and we have the reason to do this because we want to. To completely insulate or separate each of these sheets of metal so that when we wrap the electrical current through the winding wind and winding around each of these organs, we minimize the loss of ED current and hysteresis, then we begin to magnetize an e electromagnetic field and call. The core's job is to direct this magnetic field so that we Get a high magnetic field density or magnetic flux so that's what this core is doing so we got our limbs 1 2 the got the top and bottom of the core and the core itself consists of a very thin steel lamination that has been clamped together.

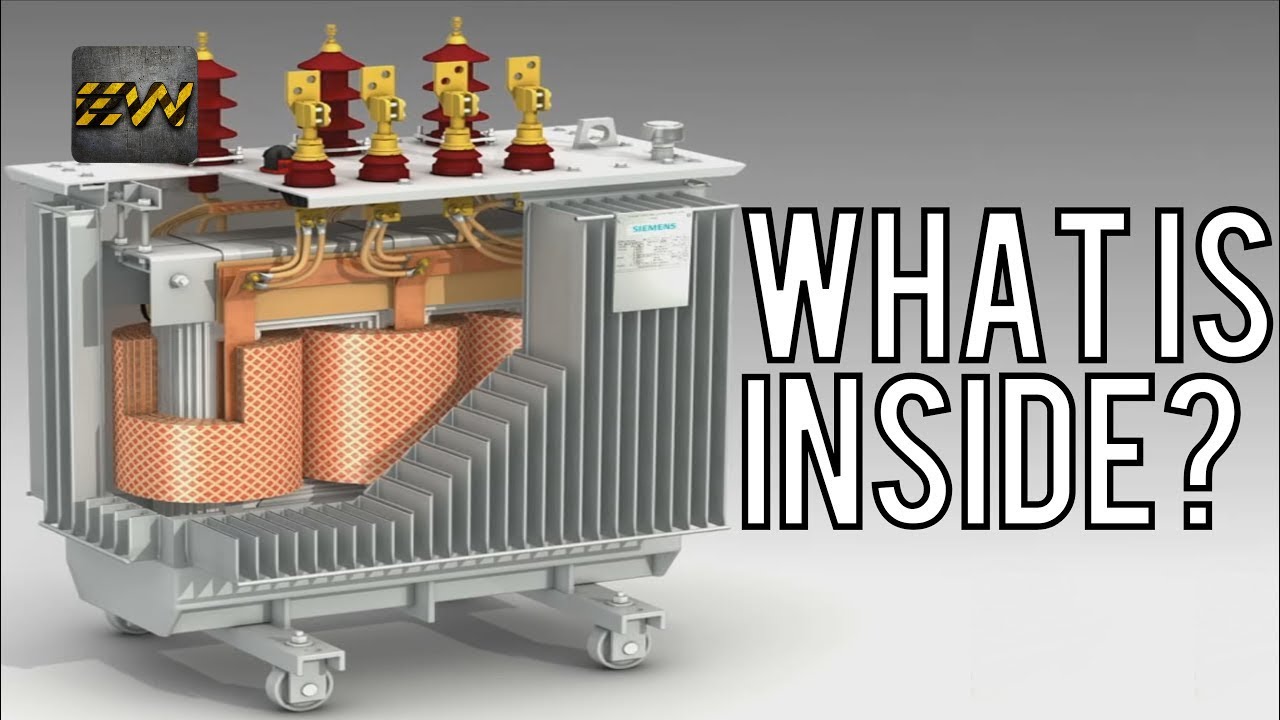

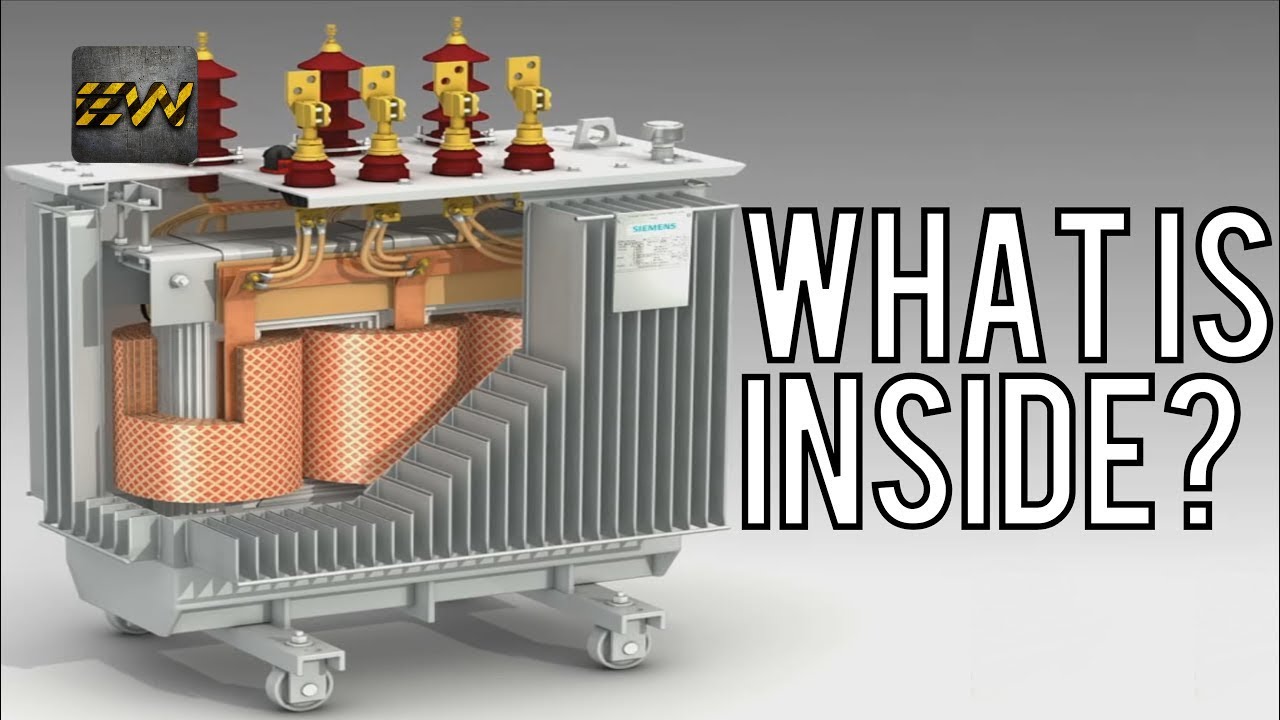

Usually they are separated from each other using some form of lacquer or coating and then all of them are done once. Together we are going to clamp it together or maybe glue it together and it is our transformer core that holds the original assembly we are looking at the rest of the assembly so that we see a section at the bottom here to protect the core of the transformer's base. To make sure it doesn't rotate and we can see it at the top as well as the top of the tank We also have an establishment to protect it and again any of these movements will stop. The casing of this type of core inside the transformer can be used for dry type transformer. It does not change the design of the Hermetic type transformer or the transformer type of the conservator. General Chat Chat Lounge - At that point, like the transformer is currently showing, so now we have to look at the transformer core. Let's go ahead and look at the next item on the list that you can see now that we are looking at. Dry type transformer is a type of transformer which is not insulated by liquid and can be of liquid oil or maybe some type of synthetic oil or biodegradable oil but it is also a dry type transformer.

Which is sometimes referred to as one. Cast Resin Type Transformer We can see that it has got wheels at the bottom to move it into position and we've got these great pieces to cool this transformer. If we go up we can see the connections behind the transformer. We break it down into its components. You can see that there are a lot of them, which is that core again because we were looking at first I can see if I can assemble it slightly or we can see the actual shape of the core together. As you can see there are stripes that we are talking about before. These stripes are used to clamp the core together and Backe will come down, okay, now has been on the top of the cores. Unfortunately the installed one does not get a good chance to see it and there are fewer voltage connections coming

So let's hang in there and we can start by looking at the heart of the transformer which is to convert the core so here we have a 3D model of the transformer core. We will spin a little bit because you can see that the core has three limbs and these three organs inform us. Is that this is a three phase transformer and the bottom of the transformer core is known as Yoke and in the middle these three to two Dow is known as organs of each factor is associated with one phase. The transformer core itself is usually clamped together using adhesive or some stripes. If we look at the bottom here you can see these three stripes are here and you will see that there are also two or three stripes on the other side so that the transformer core is clamped together. And it is clamped together because the core is not a solid block of metal is actually a series of metal sheets. Before we got these straight lines, these straight lines show us that the sheets are of different geometry and that you have clamped them together, you can get this wavy pattern if we can see I can do this. It can also go to another limb and look here and that is because the core is no longer cylindrical, because we have clamped these very thin laminate sheets together in the car. That we want to reduce the current losses and Eddie histresisa.

So we will clamp all the sheets of metal together. One of the organs is formed and then we will plant the metal sheet pieces together, each sheet is now insulated from its neighbor in order to form the nooks and the bottom of the transformer call and we have the reason to do this because we want to. To completely insulate or separate each of these sheets of metal so that when we wrap the electrical current through the winding wind and winding around each of these organs, we minimize the loss of ED current and hysteresis, then we begin to magnetize an e electromagnetic field and call. The core's job is to direct this magnetic field so that we Get a high magnetic field density or magnetic flux so that's what this core is doing so we got our limbs 1 2 the got the top and bottom of the core and the core itself consists of a very thin steel lamination that has been clamped together.

Usually they are separated from each other using some form of lacquer or coating and then all of them are done once. Together we are going to clamp it together or maybe glue it together and it is our transformer core that holds the original assembly we are looking at the rest of the assembly so that we see a section at the bottom here to protect the core of the transformer's base. To make sure it doesn't rotate and we can see it at the top as well as the top of the tank We also have an establishment to protect it and again any of these movements will stop. The casing of this type of core inside the transformer can be used for dry type transformer. It does not change the design of the Hermetic type transformer or the transformer type of the conservator. General Chat Chat Lounge - At that point, like the transformer is currently showing, so now we have to look at the transformer core. Let's go ahead and look at the next item on the list that you can see now that we are looking at. Dry type transformer is a type of transformer which is not insulated by liquid and can be of liquid oil or maybe some type of synthetic oil or biodegradable oil but it is also a dry type transformer.

Which is sometimes referred to as one. Cast Resin Type Transformer We can see that it has got wheels at the bottom to move it into position and we've got these great pieces to cool this transformer. If we go up we can see the connections behind the transformer. We break it down into its components. You can see that there are a lot of them, which is that core again because we were looking at first I can see if I can assemble it slightly or we can see the actual shape of the core together. As you can see there are stripes that we are talking about before. These stripes are used to clamp the core together and Backe will come down, okay, now has been on the top of the cores. Unfortunately the installed one does not get a good chance to see it and there are fewer voltage connections coming

0 Comments